Modern vehicles are no longer just mechanical machines — they are software-driven systems running on complex embedded architectures. As the demand for reliability, scalability, and interoperability in automotive software increases, AUTOSAR has emerged as the backbone of standardization across the industry.

In this post, we’ll explore:

- What is AUTOSAR?

- Why we need AUTOSAR?

- How many components are there in AUTOSAR?

- How OEMs are utilizing AUTOSAR in their development today?

1️⃣ What is AUTOSAR?

AUTOSAR stands for AUTomotive Open System ARchitecture — it is a worldwide development partnership of automotive OEMs, Tier-1 suppliers, and software companies. It defines a standardized software architecture for automotive ECUs (Electronic Control Units), promoting modularity, scalability, and reusability of software across vehicle platforms and manufacturers. There are two main platforms under AUTOSAR:

- Classic Platform (CP): for real-time, low-resource ECUs

- Adaptive Platform (AP): for high-performance computing, used in ADAS, infotainment, etc.

2️⃣ Why Do We Need AUTOSAR?

Before AUTOSAR, every OEM or supplier developed their own proprietary software for ECUs, resulting in:

- Code duplication

- Poor software reusability

- Hard-to-maintain systems

- Longer development time and higher cost

AUTOSAR addresses these issues by:

- Standardizing interfaces between software modules

- Allowing independent development of software components

- Providing hardware abstraction through layered architecture

- Enabling separation of software and hardware concerns

In short, AUTOSAR allows companies to build more reliable, interoperable, and future-proof automotive software.

3️⃣ How Many Components Are There in AUTOSAR?

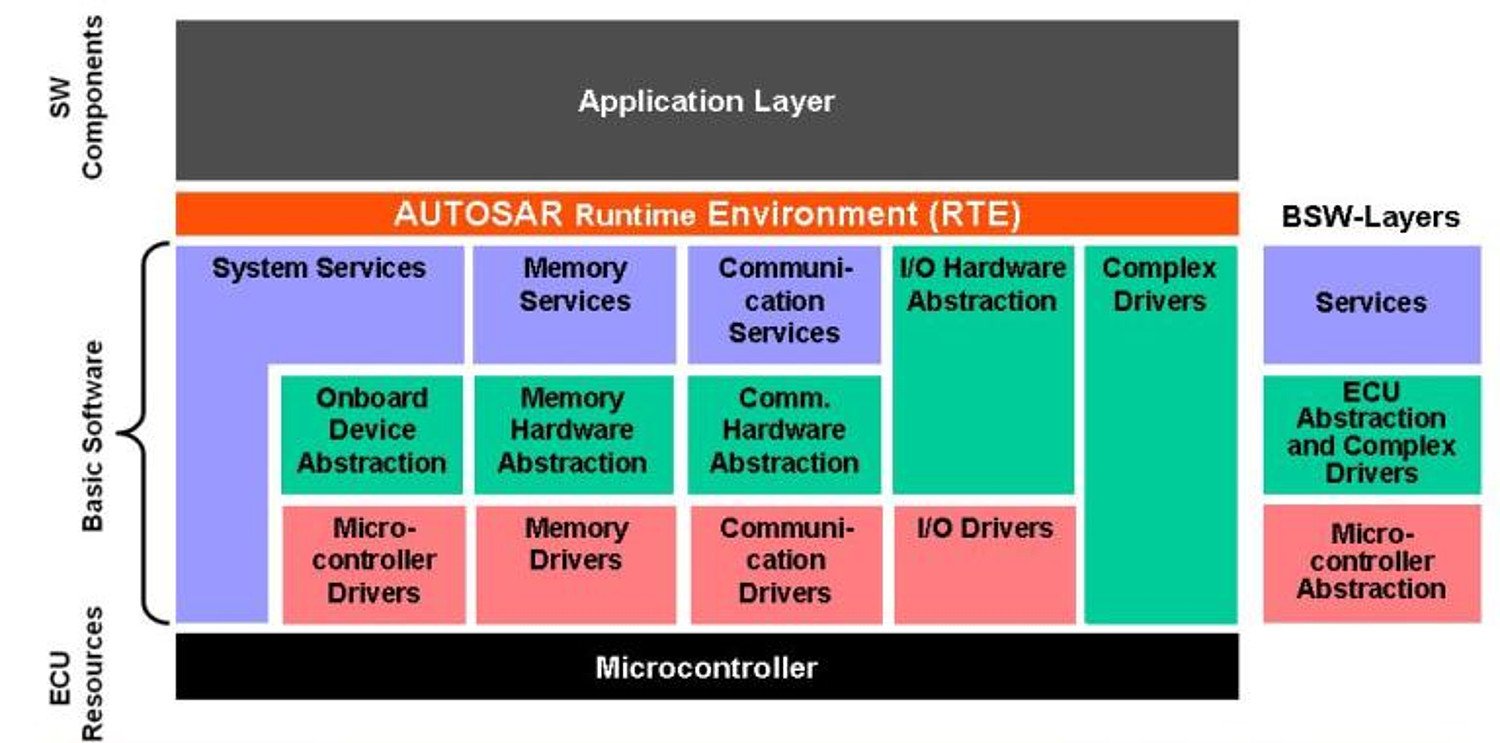

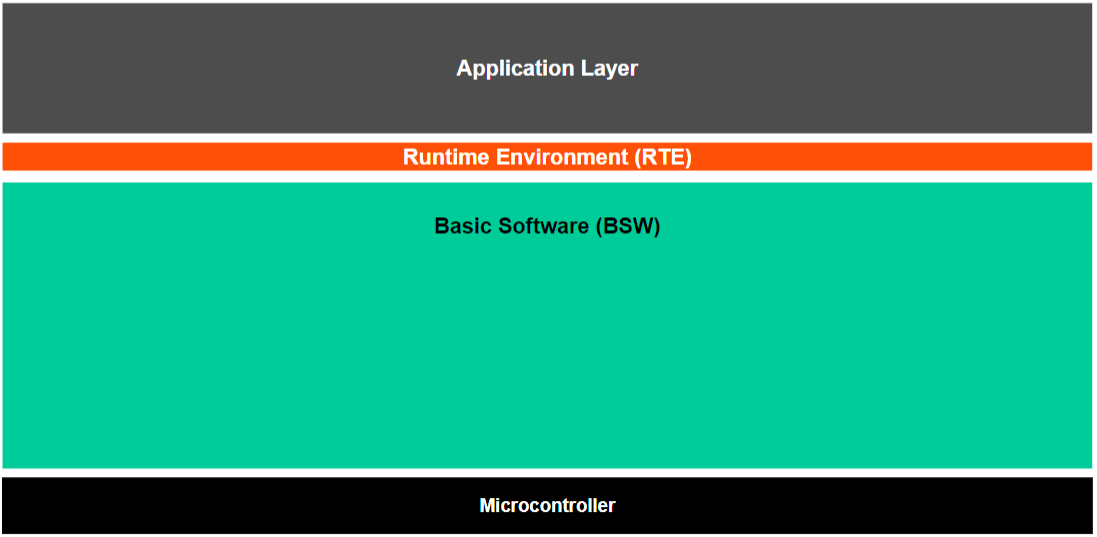

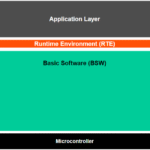

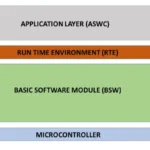

AUTOSAR Classic Platform is designed around a layered architecture, consisting of the following major components:

🔹 Application Layer

- Contains Software Components (SWCs) that implement vehicle features

- Completely hardware-independent

🔹 Runtime Environment (RTE)

- Middleware layer that connects SWCs to lower layers (BSW)

- Auto-generated during build time

🔹 Basic Software (BSW)

Divided into several layers:

- Services Layer: OS, communication stack, memory services, diagnostics

- ECU Abstraction Layer: Provides abstraction for external devices (ADC, PWM, CAN controller, etc.)

- Microcontroller Abstraction Layer (MCAL): Interfaces directly with hardware

- Complex Drivers: Custom drivers bypassing some layers if needed

🔹 System Description & Methodology

- Describes how ECUs, SWCs, and configurations are modeled, validated, and generated using tools

4️⃣ How Are OEMs Using AUTOSAR Today?

Most major automotive OEMs, such as BMW, Volkswagen, Toyota, Ford, Mercedes-Benz, and Hyundai, use AUTOSAR in their development pipelines today.

Key usage patterns:

- ✅ Code reusability across different car platforms

- ✅ Supplier collaboration using standard interfaces and contracts

- ✅ Tool-based configuration and code generation using tools like DaVinci Developer, EB tresos, or Vector GENy

- ✅ ECU abstraction for faster hardware migration

- ✅ Integration of third-party software (e.g., AUTOSAR stacks from suppliers like Vector, Elektrobit, ETAS)

📈 Growing Trend:

- Transition from Classic to Adaptive Platform for high-end ECUs running POSIX OS (Linux, QNX)

- Integration with Service-Oriented Architecture (SOA) and vehicle-wide Ethernet networks

- AUTOSAR is now a cornerstone for software-defined vehicles (SDVs)

Conclusion

AUTOSAR is not just a software framework — it’s an industry-wide movement toward building safer, scalable, and smarter vehicles. Whether you’re a student, engineer, or developer just starting with automotive systems, understanding AUTOSAR is essential to working in the modern automotive domain. Stay tuned for upcoming posts where we’ll dive into AUTOSAR layers, MCAL, RTE, and toolchains used in real-world projects. Happy learning!

(This post is written with the support of AI)

Leave a Reply